Hazardous Area Heating and Controls

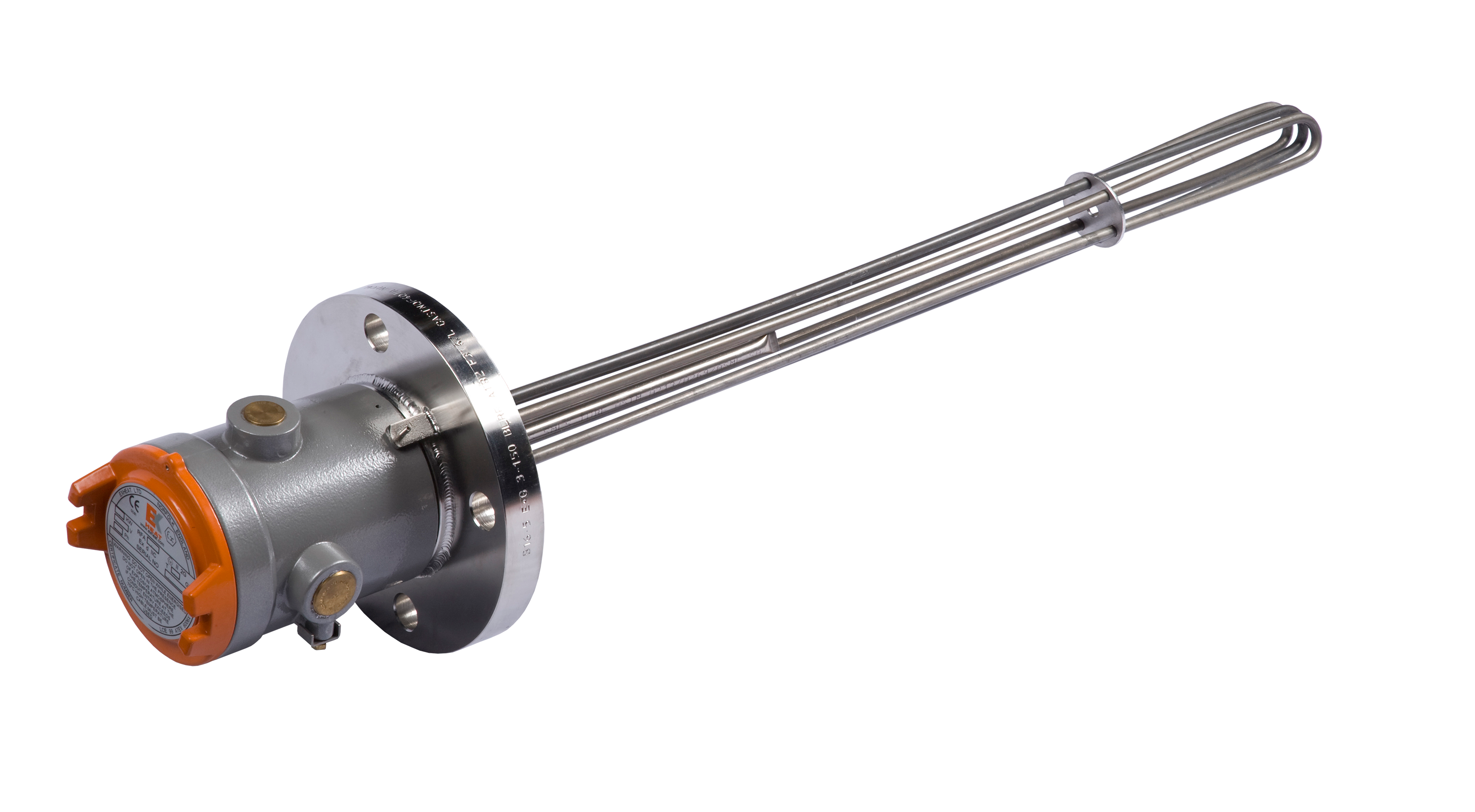

RFA Flameproof Rod-Type Immersion Heaters

<-- Previous Next -->The RFA range of flameproof rod-type immersion heaters is suitable for installation in process tanks, safety showers, engine sumps, pressure vessels and similar plants located in Zone 1 and Zone 2 hazardous areas, where the flammable atmosphere is a IIA, IIB or IIC Gas Group. They are suitable for heating all process liquids or gases which are non-corrosive to the materials of construction.

Features

- Certified to ATEX standards

- Lightweight cast aluminium alloy terminal enclosure with weatherproof protection to IP66 and IP67

- Choice of built in process temperature sensors

- Suitable for ambient temperatures -40°C to +40°C

- Mounting of the heater can be by a threaded boss or an industry standard flange

- Designed for horizontal installation (vertical mounting available on request)

Applications

- Acid Reactor System

- Aggressive Water

- Air Line Heaters

- Amine Storage Tank

- Anodising

- Aresol Can Tester

- Bilge Tanks

- Biodiesel

- Biogas Purification System

- Boiler Equipment

- Buffer Vessel (Water)

- Bywash System

- Calorifier

- Calorifier Packages

- Calorifier Skid

- Catalyst Oxidation

- Caustic

- Caustic Solution

- Caustic Tank

- Chemical Bath

- Chemical Cleaning Tank

- Chemical Injection Systems

- Chemical Mixing Tank

- Chemical Plant Warehouses

- Chemical Plants

- Chemical Tanks

- Cleaning and Rinsing Equipment

- Cleaning and Rinsing Tanks

- Cleaning Solution

- Cleaning Solution / Caustic

- Cleaning System

- Cleaning Water Tank

- Closed Loop Systems for Bitumen

- Cold Start Up

- Compressor - CW Heater

- Compressor - Lube Oil

- Compressor - Water/Glycol

- Cooking Oil Transportation

- Coolant

- Cooling Tower

- Crank Case Heater

- Crankcase

- Crankcase Heater

- Crude Oil

- Crude Oil Maintenance Line

- De-greasing Tank

- De-Ionised Water

- De-Ionized Water

- De-Min Hot Water Tank Package

- Dehydration Gas Plant

- Deluge Skid

- Demi Water

- Dies & Platens

- Diesel Heater

- Diesel Oil Tank

- Diesel Tank Heater

- Drier System

- Drum Heating

- Drying Ovens

- Emergency Showers

- Ethylene Tank

- Eyewash Stations

- Filtration System

- Finishing

- Fire Equipment Skids

- Fire Extinguishing Equipment

- Flushing Rig for Oil Reservoir

- Food Processing Equipment

- FPSO

- Fuel Oil

- Fuel Oil Heating

- Fuel Oil Reservoir

- Fuel Oil Tank

- Fuel Oil Tanks

- Gas Bottles

- Gas Installations

- Gas Regeneration

- Gear Box Oil

- Gear Oil

- Gear Oil Tank

- Gearbox Oil

- GLNG Natural Gas Train Gas Supply

- Glycol

- Hazardous Area Showers

- HCL solution

- Heat Transfer Fluid

- Heat Transfer Oil Tank/System

- Heat Transfer Oils

- Heated Showers

- Heating Medium

- High Pressure Wash System

- High Pressure Washers

- Hot Swills

- Hot Water Calorifier

- Hot Water Heating System

- Hot Water Sanitiser

- Hot Water Storage

- Hot Water Storage Tanks

- Hot Water Tank

- Hot Water Wash System

- Hydraulic Oil - Tank/Reservoir

- Hydraulic Oil Drums

- Hydraulic Oil Package

- Hydraulic Oil Tank

- Hydraulic Power Pack

- Increase Flow of Viscous Liquids

- Indirect Heating of Liquids

- Industrial washing and rinsing processes

- Industrial Washing Machine

- Industrial Water Heating

- Inline Diesel

- Kinetic Hydrate Inhibitor

- Laboratories

- Laboratory Chemical

- LNG Oil Separator

- Lube Oil

- Lube Oil Centrifuge Skid

- Lube Oil Console

- Lube Oil Coolers for Gas Turbines

- Lube Oil for Flushing System

- Lube Oil for Refrigeration Package

- Lube Oil Heater

- Lube Oil Reservoir

- Lube Oil System

- Lube Oil Tanks - Gas Compressor Trains

- Lubricant Oil

- Machinery and Plant Construction

- Melting of Solids (Paraffin)

- Methane Digester

- Mineral Oil

- Molasses (Syrup)

- Motor/Generator

- Moulds

- Nitric Acid Solution

- Offshore Heating Vessel

- Offshore Installation

- Offshore Platform

- Offshore Water Tank

- Oil / Water Mix

- Oil / Water Mixture

- Oil & Lubricant Store

- Oil & Water

- Oil Additive Injection Tank/System

- Oil Gearbox heater

- Oil Line Heater

- Oil Purifier System

- Oil Recycling & Filtration System

- Oil Refineries

- Oil Reservoir

- Oil Separator

- Oil Separator Heater

- Oil Storage Tanks

- Oil Sump

- Oil Sump Heaters

- Oil Sump Heating

- Oil System Unit

- Oil Tank

- Oil Tanker

- Oil Tanks

- Oil Top-Up Tank

- Oil/Water Mix

- Paint Machinery

- Paraffin

- Pasteurisation

- Petrochemical Plant

- PFD Liquid

- Phosphate Water

- Plant

- Portable Showers

- Potable Water

- Pour Point Depressant

- Power Engineering

- Pre-heating Hydraulic Oil

- Pre-Heating Oil and Water

- Pre-heating Water for Paint Sys

- Pressure Washers

- Process and Boiler Equipment

- Processing Equipment

- Propane Refirgeration Package

- Pulp Heating System

- Pumps

- Purified Water / Pharmaceutical

- Purified Water Circulating System

- Purified Water System

- Quench Tank

- Re-circulating Oil System

- Reactor System in Zinc Silicate Production

- Refinery - Lube Oil

- Refrigeration

- Reservoir Heater

- Reverese Osmosis Water

- Reverse Osmosis

- Reverse Osmosis System

- Safety Shower

- Safety Showers

- Salt Water Tank

- Sanitary Discharge System

- Sea Water

- Sea Water for Treatment

- Sewage Plants

- Shower Unit

- Silo-Skirt Heater

- Skid

- Slurry Heater

- Solvent Recovery Plant

- Start Up for Lube Oil - Compressors

- Steam Turbine Lubrication Tank

- Sterilizing

- Sterilizing Sink

- Substation

- Sugar Refinieries

- Swimming pool

- Tank Heating

- Tank Showers

- Temperature Maintenance of Storage Tanks

- Test Rig

- Thermic Oil for Steel Rollers

- Transformer Lube Oil System

- Under floor heateing schemes

- Underground Hydraulic Power Unit

- Urethane Remover

- Vacuum Pump Lube Oil

- Vat Heating

- Vegetable Oil

- Ventilation and Refrigeration

- Wash Gun Water Tank

- Wash Rooms

- Wash Stations

- Washdown/Sanitizing System

- Washer System

- Washing Equipment

- Washing Machines

- Waste Water Treatment

- Water

- Water Boiler

- Water Buffer Tank

- Water Circulating

- Water For Injections

- Water Heater

- Water Heater on Vacuum System

- Water in Distillery

- Water Pump House

- Water Recirculation for CIP System

- Water Storage

- Water Storage Room

- Water System

- Water Tank

- Water Tank - Pump Package

- Water Treatment

- Water Treatment System Container

- Water Vapouriser

- Water Vat

- Water Wash Cart

- Water/Amine Solution

- Water/Chemical Frost Protection

- Water/Cleaning Solution Tank

- Water/Glycol

- Water/Glycol for Leachate Treatment

- Water/Glycol Re-circulation

- Water/Glycol Reservoir

- Water/Oil Separator Unit

- Water/Phosphate Solution

- Water/Soap

- Water/Steam

- Wax Inhibitor

- Wort/Brewery

- Worts/Caustic Solution

Model

Specifications

| Certification | ATEX  II 2 G II 2 GEx d IIC T3 to T6 Gb Zone 1 and 2 CU TR (EAC) |

|---|---|

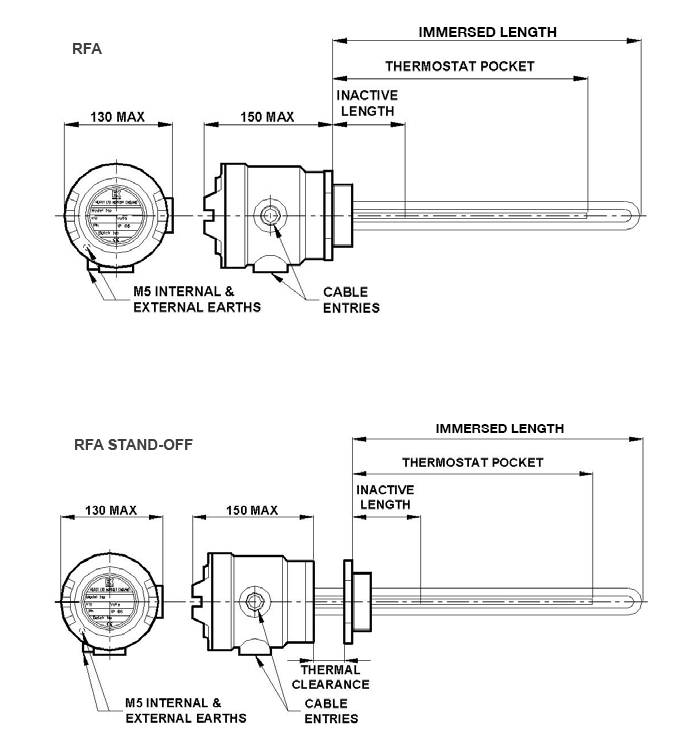

| Enclosure | Cast aluminium alloy with a maximum of one M20 and one M25 cable entry, external and internal earths and screwed terminal cover; certified Ex d IIC T4 to T6 with the option of T3 to T6, where the terminal enclosure is stood away from the processing equipment |

| Elements | A maximum of three rod-type elements, comprising 80/20 nickel chrome resistance wire, compacted in high purity magnesium oxide insulating powder and encased in either Incoloy 800, 825 or 316L, 304 or 321 stainless steel, secured by either brazing or welding, depending upon the process application |

| Controls | Heater over temperature protection is fitted as standard |

| Mounting | Any threaded NPT or BSP boss or flange in any material can be specified within the limits of the design parameters; heaters can be either 'direct-on' or 'standoff' as required by the certification |

| Rating | 12kW (water applications) and up to 3kW (light-medium oil applications) |

| Voltage | Any electrical supply up to 690V |