Hazardous Area Heating and Controls

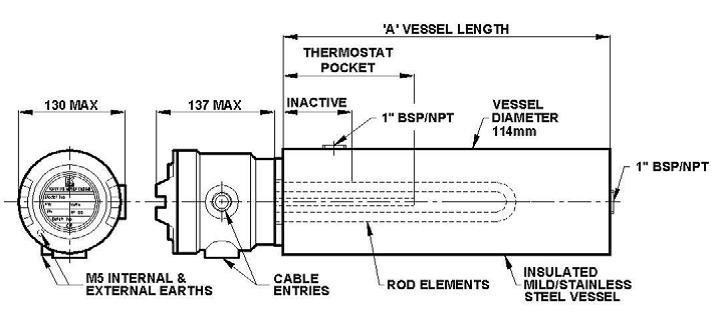

FP-MLH Flameproof Mini Line Heaters

<-- Previous Next -->The range of flameproof mini line heaters consist of a screw plug or flanged type immersion heater mounted in a thermally insulated heating vessel, and is designed to efficiently transfer heat to a flowing medium (liquid, air or gas). The FP-MLH range is certified for use in hazardous areas where the atmosphere is classified as a Zone 1 or 2 (IIA, IIB, IIC) gas group.

Download Documents:

Features

- Certified to ATEX standards

- Weatherproof protected to IP66 or NEMA 4 (FP4-MLH only)

- Choice of built in process temperature sensors and externally adjustable option

- Mild steel or 316 stainless steel vessel

- Suitable for ambient temperatures from -40°C to +40°C (FP-MLH) and -60°C to +60°C (FP4-MLH)

- Standard range of high quality Incoloy or stainless steel rod-type elements, designed for water or withdrawable ceramic core elements, designed for oil

- Maximum allowable working pressure up to 10 barg / 145 psig, subject to design parameters

- Designed for both horizontal and vertical installation (if mounted vertically, terminal box must be located at the bottom)

- FP4-MLH range available with multi approvals

Applications

- Accumulator System Cabinet

- Acid Reactor System

- Acoustic Enclosure

- Aggressive Water

- Air Line Heaters

- Amine Storage Tank

- Anodising

- Anti Condensation Heater

- Anti-Freeze

- Aresol Can Tester

- Battery Cabinet Heater

- Bilge Tanks

- Biodiesel

- Biogas Purification System

- Boiler Equipment

- Buffer Vessel (Water)

- Bywash System

- Cabinet

- Calorifier

- Calorifier Packages

- Calorifier Skid

- Cat Diesel Engine

- Catalyst Oxidation

- Caustic

- Caustic Solution

- Caustic Tank

- Chemical Bath

- Chemical Cleaning Tank

- Chemical Injection Cabinet

- Chemical Injection Systems

- Chemical Mixing Tank

- Chemical Plant Warehouses

- Chemical Plants

- Chemical Tanks

- Cleaning and Rinsing Equipment

- Cleaning and Rinsing Tanks

- Cleaning Solution

- Cleaning Solution / Caustic

- Cleaning System

- Cleaning Water Tank

- Closed Loop Systems for Bitumen

- Cold Start Up

- Compressor - CW Heater

- Compressor - Lube Oil

- Compressor - Water/Glycol

- Compressor Enclosure

- Compressor Frame Enclosure

- Cooking Oil Transportation

- Coolant

- Cooling Tower

- Crane Engine

- Crank Case Heater

- Crankcase

- Crankcase Heater

- Crude Oil

- Crude Oil Maintenance Line

- De-greasing Tank

- De-Ionised Water

- De-Ionized Water

- De-Min Hot Water Tank Package

- Dehydration Gas Plant

- Deluge Skid

- Demi Water

- Dies & Platens

- Diesel Generator Enclosure

- Diesel Heater

- Diesel Oil Tank

- Diesel Tank Heater

- Drier System

- Drum Heating

- Drying Ovens

- Emergency Showers

- Enclosure

- Engine Bay

- Engine Jacket Pre-Heating

- Engine Pre-Coolant Heaters

- Ethylene Tank

- Eyewash Stations

- Filtration System

- Finishing

- Fire Equipment Cabinet

- Fire Equipment Skids

- Fire Extinguishing Equipment

- Flushing Rig for Oil Reservoir

- Food Processing Equipment

- FPSO

- Frost Protection

- Fuel Oil

- Fuel Oil Heating

- Fuel Oil Reservoir

- Fuel Oil Tank

- Fuel Oil Tanks

- Gas Bottles

- Gas Installations

- Gas Regeneration

- Gear Box Oil

- Gear Oil

- Gear Oil Tank

- Gearbox Oil

- GLNG Natural Gas Train Gas Supply

- Glycol

- GRP Enclosure

- Hazardous Area Showers

- HCL solution

- Heat Transfer Fluid

- Heat Transfer Oil Tank/System

- Heat Transfer Oils

- Heated Showers

- Heater Jacket

- Heating Cabinet

- Heating Medium

- High Pressure Wash System

- High Pressure Washers

- Hot Swills

- Hot Water Calorifier

- Hot Water Heating System

- Hot Water Sanitiser

- Hot Water Storage

- Hot Water Storage Tanks

- Hot Water Tank

- Hot Water Wash System

- Hydraulic Oil - Tank/Reservoir

- Hydraulic Oil Drums

- Hydraulic Oil Package

- Hydraulic Oil Tank

- Hydraulic Power Pack

- Increase Flow of Viscous Liquids

- Indirect Heating of Liquids

- Industrial washing and rinsing processes

- Industrial Washing Machine

- Industrial Water Heating

- Inline Diesel

- Kinetic Hydrate Inhibitor

- Laboratories

- Laboratory Chemical

- LNG Oil Separator

- Lube Oil

- Lube Oil Centrifuge Skid

- Lube Oil Console

- Lube Oil Coolers for Gas Turbines

- Lube Oil for Flushing System

- Lube Oil for Refrigeration Package

- Lube Oil Heater

- Lube Oil Reservoir

- Lube Oil System

- Lube Oil Tanks - Gas Compressor Trains

- Lubricant Oil

- Machine Enclosure

- Machinery and Plant Construction

- Melting of Solids (Paraffin)

- Methane Digester

- Mineral Oil

- Molasses (Syrup)

- Motor Cases/Enclosures

- Motor Enclosure

- Motor/Generator

- Moulds

- Nitric Acid Solution

- Offshore Cabinet

- Offshore Heating Vessel

- Offshore Installation

- Offshore Platform

- Offshore Water Tank

- Oil / Water Mix

- Oil / Water Mixture

- Oil & Lubricant Store

- Oil & Water

- Oil Additive Injection Tank/System

- Oil Gearbox heater

- Oil Line Heater

- Oil Purifier System

- Oil Recycling & Filtration System

- Oil Refineries

- Oil Reservoir

- Oil Separator

- Oil Separator Heater

- Oil Storage Tanks

- Oil Sump

- Oil Sump Heaters

- Oil Sump Heating

- Oil System Unit

- Oil Tank

- Oil Tanker

- Oil Tanks

- Oil Top-Up Tank

- Oil/Water Mix

- Outdoor Telecommunications Cabinet

- Paint Machinery

- Paraffin

- Pasteurisation

- Petrochemical Plant

- PFD Liquid

- Phosphate Water

- Plant

- Portable Showers

- Potable Water

- Pour Point Depressant

- Power Engineering

- Pre-heating Hydraulic Oil

- Pre-Heating Oil and Water

- Pre-heating Water for Paint Sys

- Pressure Washers

- Process and Boiler Equipment

- Processing Equipment

- Propane Refirgeration Package

- Pulp Heating System

- Pump Enclosure Safety Stat

- Pumps

- Purified Water / Pharmaceutical

- Purified Water Circulating System

- Purified Water System

- Quench Tank

- Re-circulating Oil System

- Reactor System in Zinc Silicate Production

- Refinery - Lube Oil

- Refrigeration

- Reservoir Heater

- Reverese Osmosis Water

- Reverse Osmosis

- Reverse Osmosis System

- Safety Shower

- Safety Showers

- Salt Water Tank

- Sanitary Discharge System

- Sea Water

- Sea Water for Treatment

- Sewage Plants

- Shower Unit

- Silo Base Enclosure warming

- Silo-Skirt Heater

- Skid

- Skid Enclosure

- Slurry Heater

- Solvent Recovery Plant

- Start Up for Lube Oil - Compressors

- Steam Turbine Lubrication Tank

- Sterilizing

- Sterilizing Sink

- Substation

- Sugar Refinieries

- Swimming pool

- Tank Heating

- Tank Showers

- Temperature Maintenance of Storage Tanks

- Test Rig

- Thermic Oil for Steel Rollers

- Transformer Enclosures

- Transformer Lube Oil System

- Transmitter Enclosures

- Under floor heateing schemes

- Underground Hydraulic Power Unit

- Urethane Remover

- Vacuum Pump Lube Oil

- Vat Heating

- Vegetable Oil

- Ventilation and Refrigeration

- Wash Gun Water Tank

- Wash Rooms

- Wash Stations

- Washdown/Sanitizing System

- Washer System

- Washing Equipment

- Washing Machines

- Waste Water Treatment

- Water

- Water Boiler

- Water Buffer Tank

- Water Circulating

- Water Cooled Engines

- Water For Injections

- Water Heater

- Water Heater on Vacuum System

- Water in Distillery

- Water Jacket

- Water Jacket Heater

- Water Pump House

- Water Recirculation for CIP System

- Water Storage

- Water Storage Room

- Water System

- Water Tank

- Water Tank - Pump Package

- Water Treatment

- Water Treatment System Container

- Water Vapouriser

- Water Vat

- Water Wash Cart

- Water/Amine Solution

- Water/Chemical Frost Protection

- Water/Cleaning Solution Tank

- Water/Glycol

- Water/Glycol for Leachate Treatment

- Water/Glycol Re-circulation

- Water/Glycol Reservoir

- Water/Oil Separator Unit

- Water/Phosphate Solution

- Water/Soap

- Water/Steam

- Wax Inhibitor

- Wort/Brewery

- Worts/Caustic Solution

Model

| Model | FP-MLH1S | FP-MLH2S | FP-MLH3S | FP-MLH6S | FP-MLH9S | FP-MLH3L | FP-MLH6L | FP-MLH9L | FP-MLH12L | FP-MLHX1 | FP-MLHX2 | FP-MLHX3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Loading (kW) | 1 | 2 | 3 | 6 | 9 | 3 | 6 | 9 | 12 | 1 | 2 | 3 |

| Dim A (mm) | 475 | 475 | 475 | 475 | 475 | 925 | 925 | 925 | 925 | 925 | 925 | 925 |

| BSP/NPT | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' | 1'' |

Specifications

| Certification | ATEX  II 2 G II 2 GEN 60079-0, EN 60079-1, EN 60079-7, EN 60079-31 Ex d IIC T4 to T6 Gb Zone 1 and 2 CU TR (EAC) *FP4-MLH also certified to ATEX / IECEx, CSA, Inmetro, KGS, CNEx, CCOE |

|---|---|

| Enclosure | Cast aluminium alloy with a maximum of one M20 and one M25 cable entry, external and internal earths and screwed terminal cover (FP4-MLH - mild steel or 316 stainless steel) |

| Elements | High quality nickel chrome resistance wire compacted in magnesium oxide insulating powder and sheathed in corrosion resistant Incoloy 825/800, 316L stainless steel, withdrawable ceramic core elements housed in mild steel or 316L stainless steel tube |

| Pressure | Maximum allowable working pressure up to 10 barg / 145 psig subject to design parameters |

| Design Code | Sound Engineering Practice (SEP) |

| Vessel | Mild steel or stainless steel |

| Insulation | Mineral wool |

| Cladding | Coated mild steel or 304 stainless steel |

| Voltage | Standard units are normally designed for 220V to 254V (1 phase) or 380 to 440V (3 phase) |